About Us

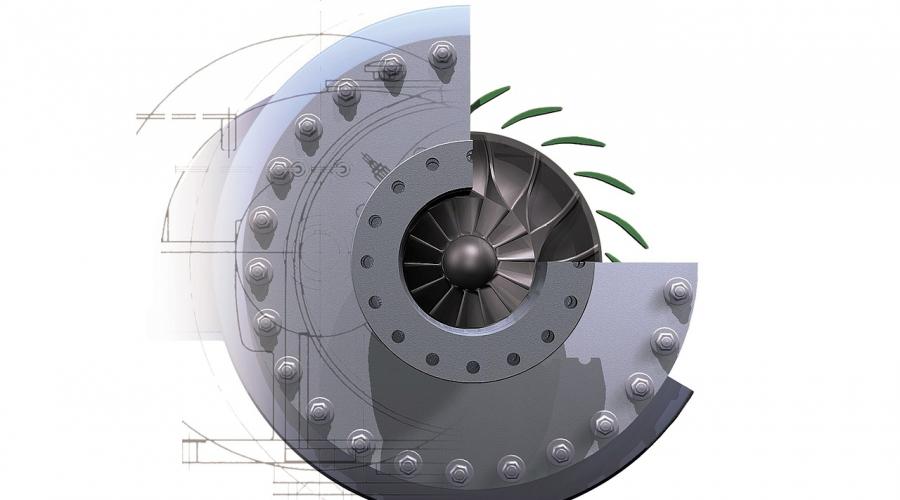

Pattern Making

The process is fast and it reduces the cost.

CNC Machining

Our extensive industry expertise allows us to provide efficient CNC machining:

- Fully machined wood and / or 3D printed CNC patterns.

- Patterns built to foundry specifications or customized based to your requirements.

- Short-run or full production pattern options.

Problem Solving

Our Portofolio

Success depends on how well business partners collaborate and react to changes in design and process,

regardless of their geographical location!

” The future of the foundry industry is completely depent on the training of young men to replace those craftsmen who retire or pass on. Remember, no pattern, no casting! It is as simple as that.”

Our Services

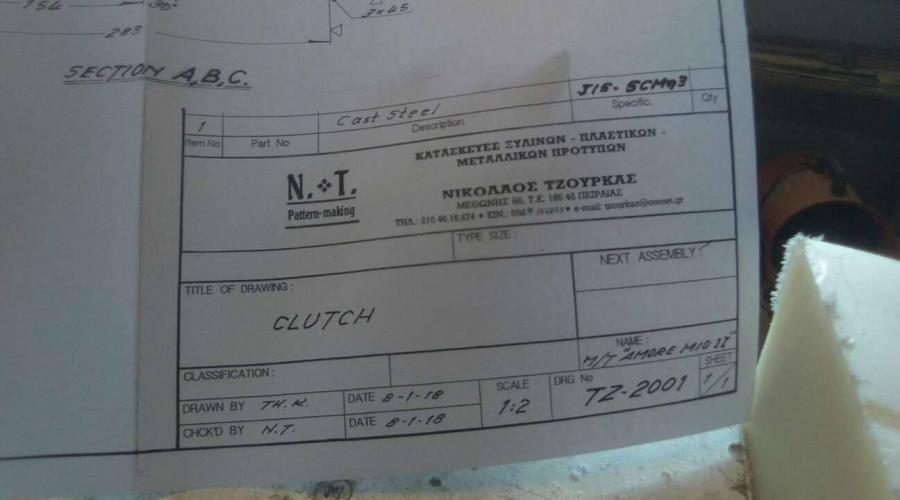

Anything you need can be custom designed to precisely match the requirements of the vessel application.

Creative and DynamicAdaptive and FlexibleEver-ready to serve you.

Spare parts are 100% CNC machined - to hair thickness accuracy over every square inch.

We deliver every order using an integrated design and manufacturing process. Computer-generated design geometry is transferred into castings. Then we put through accuracy CNC machining which guarantees the highest accuracy specific and performance for your vessel.

WHAT THEY SAYTESTIMONIALSOUR GREAT CLIENTS

"Always available when we need them with an excellent service! They were happy to help, work with my team to find solutions. Would definely recommend this company to others due to high quality professional service".

John C. Teflon

"Mr. Tzourkas and his Team were very responsive and did a wonderful work, even if we decided to make it the last minute. They were incredibly courteous and fast".

Joanna Betton

"I would really like to thank Mr. Tzourkas and his Team for their efforts. One of the most important aspects of that trust is recognition. Very quick and high quality professional service".

John Plafon

Tzourkas N. Co.isAwesomeUniqueDynamic

Quality Policy

If you have any problem, get in touch – we are here to help you!

OUR VISION

We choose wood based on a variety of factors such as stability, durability, and life expectancy of the pattern. Most patterns are comprised mainly of wood. We will also use plastic resins, epoxies, fiberglass and other composites for our foundry patterns – if necessary.

We try continually to improve our skills and knowledge which will help us carry out these values.

Our Location

Take a look around to our website to see the areas we specialise in. You are able to contact us to initiate the Instant Problem Solving process.

Telephone N.T on: (+30) 210 4616674

A.O.H.: (+30) 6977 390387

Send us a fax on: (+30) 210 4621333

Or e-mail us at: info@tzourkas.gr

MONDAY - FRIDAY

08:00 - 18:00

collars water between the water cooler and the diesel engine_900x500.jpg)